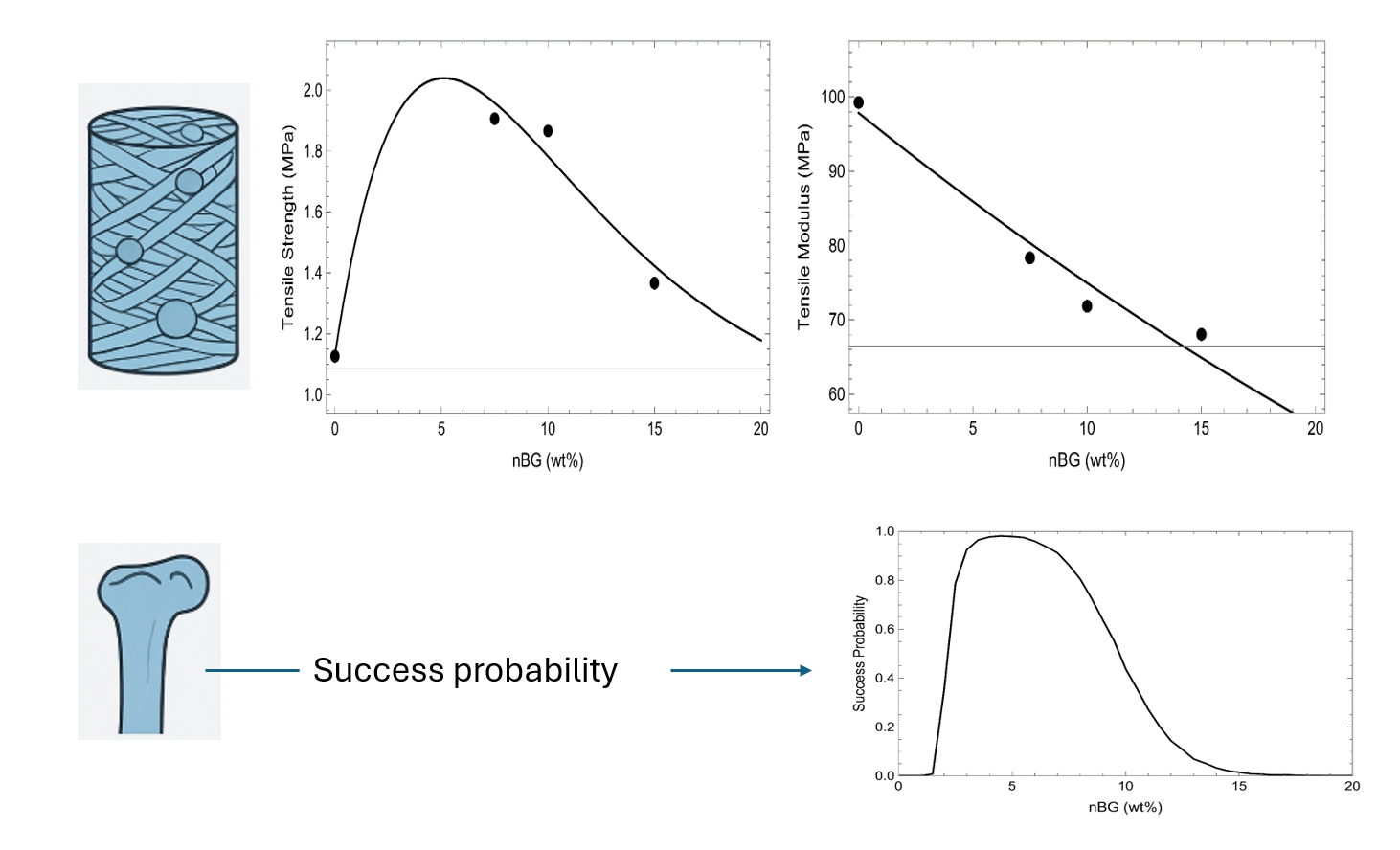

Probabilistic modeling of the tensile properties of P3HB/nBG electrospun scaffolds for bone tissue engineering applications

DOI:

https://doi.org/10.61882/jcc.7.4.4Abstract

Electrospun P3HB/nano-bioactive glass (nBG) scaffolds for bone tissue engineering exhibit a non-monotonic and sometimes conflicting dependence on nBG content, featuring an optimum tensile strength at a representative nBG loading and a monotonic decrease in elastic modulus. To provide a predictive and reliable framework for design, we developed physics-informed, semi-empirical models for tensile strength and elastic modulus. The modified rule of mixtures, with an exponential efficiency factor, accurately predicted the peak edge-level tensile strength at 7.5 wt.% nBG (R² = 0.989), and attributed the decline in tensile strength at higher loading to the agglomeration of nanoparticles. To explain the unexpected decline in modulus, we proposed an exponential decay model, which attributed the softening effect to the disruption of hydrogen bonding within the P3HB matrix by nBG nanoparticles on the surface (R² = 0.956). Additionally, we applied Monte Carlo simulations to propagate experimental uncertainty and obtain a "success probability", whereby we defined "success" to be a tensile strength of > 1.8 MPa and an elastic modulus < 80 Mpa (the scaffold properties should ultimately specify it for bone regeneration). This probabilistic framework showed that scaffolds that contained 7.5 to 10 wt.% nBG had the highest success probability (> 0.8).

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 .

This work is licensed under a Creative Commons Attribution 4.0 International License.